Marktronic InDot

- Robust ball screw mechanism guarantees dot precision required for the most demanding industrial part identification applications.

- High speed integrated marking with high level of speed/quality control allowing users to fine tune the system to exact cycle time requirements.

- Ingress protected sliding plates enable the InDot™ 60-60E and InDot™ 150-150E to be installed in the harshest of environments.

- Electric Solenoid with programmable depth settings. Capable of marking all engineering materials up to 62HRc (800Hv)

- ‘DP’ series feature a powerful pneumatic stylus assembly with marking depth up to 1 mm in mild steel, 1.5 mm in aluminium.

- ‘A’ series equipped with AutoSense™ system allowing self adjustment to variation of part batch height with the best precision, repeatability and consistency (especially well suited to Data Matrix marking). Must be installed with digital Z approach axis.

- 100 – 220v single phase supply (no pneumatics required).

- Low running costs and virtually no consumable costs.

3000 controller and software

- Separate 3000 controller protects electronics from shock loading of mechanical marking operation.

- Durable integrated membrane keyboard with LCD linked function keys.

- Very large embedded graphical display

- Simple to use menu system software with marking preview

- Advanced standard features incl. serial numbering, passwords, arc marking, time/date and logo marking etc.

- Various communication ports and I/O

- Wide Range of Options

Marking Area: 60mm x 60mm (60-60E) or 150 mm x 150 mm (150-150E)

- Std. Character Sizes: 0.15mm – 99.9mm in increments of 0.15mm

- Marking Formed: 5 x 7, 7 x 9, Varidot, HPGL, BMP Logos

- Marking Speed: Variable, depends on application

- Memory storage of up to 1350 marking programs

- 2 x RS232 and Digital I/O (8 In 6Out) Connectivity. Optional Ethernet TCP/IP

- Full QWERTY integrated membrane keyboard with addition PS/2 port for external keyboards.

- On-screen mark preview and trial-run features

- Remote Start/Stop control box

- PC Option using Pryor MarkMaster™ Graphical Software

MARKTRONIC INDOT 50-25 E Marking area: 50 x 25 mm Electromagnetic- no air required MARKTRONIC INDOT 50-25 FP Marking area: 50 x 25 mm Fast Pneumatic- air supply required MARKTRONIC INDOT 60-60E/DP Marking area: 60 x 60 mm DP version: Deep Pneumatic –air supply required E version: Electromagnetic – no air required MARKTRONIC INDOT 150-150 E/DP Marking area: 150 x 150 mm DP version: Deep Pneumatic –air supply required E version: Electromagnetic – no air required

- Custom designed fixtures available on request.

- Digital approach axis

- Pneumatic approach axis

- Remote Start/Stop box

- Footswitch start pedal

- 100mm & Custom Extended Nosepiece and Styli

- Windows Operating Software

- Barcode scanner to simplify data entry

- Compact electric Z axis with AutoSense™

- TCP/IP (10BaseT) Ethernet Module for 3000 controller

- Integrated VeriSmart™ DataMatrix verification camera and software

- DataMouse™ Pro Direct Part Mark DataMatrix Reader (PC Required)

- Extended Warranty packages available.

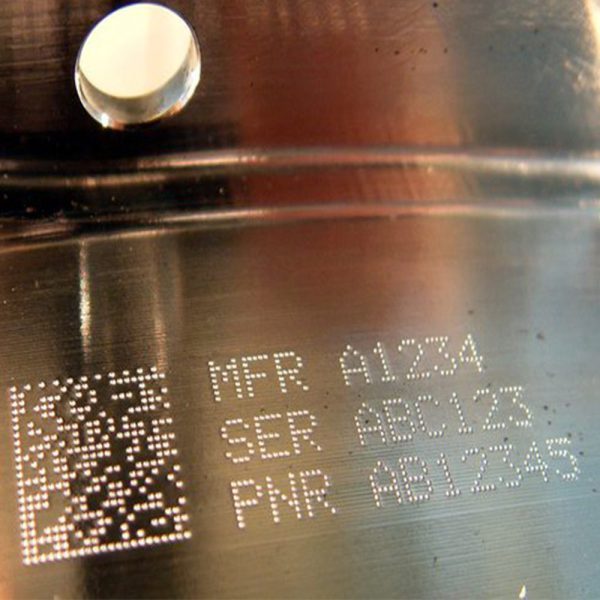

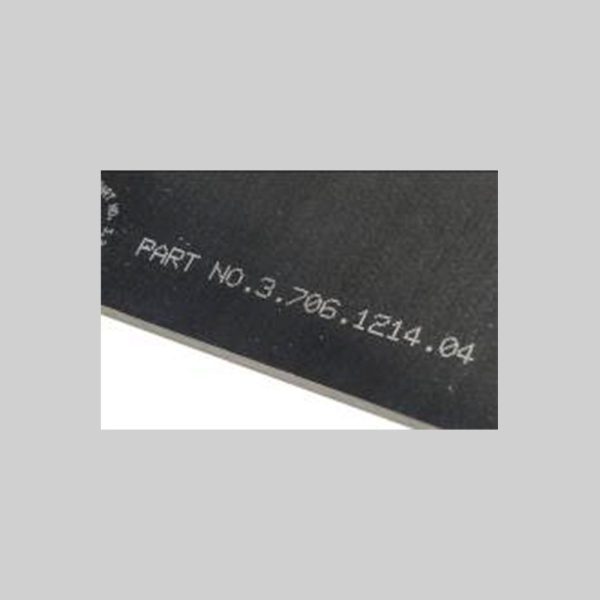

- Direct Part Marking (DPM)

- IUID MIL130 Compliance marking

- Programmable marking

- Component identification

- Component traceability

- Serial numbering

- Logo marking

- Security marking

- Health & safety appliance marking

- Certification marking

- Time and date marking

- Part numbering

- Batch and shift coding

- Calibration systems

- Label and tag marking